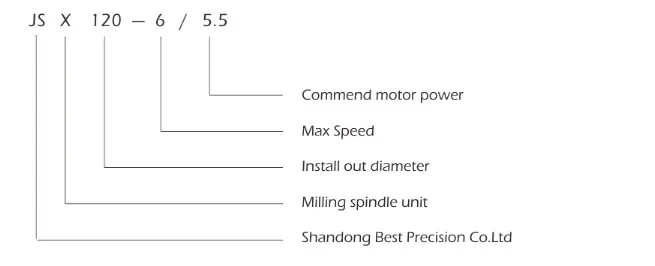

Description

Spindle Unit for CNC Machine Center

A spindle unit is a critical component of a CNC (Computer Numerical Control) machine center. It is responsible for rotating the cutting tool or workpiece at high speeds to perform various machining operations. Here are some key aspects of a spindle unit in a CNC machine center:

- Spindle Motor: The spindle motor is the power source that drives the rotation of the spindle. It is typically an electric motor, often an AC or DC motor, capable of generating high rotational speeds and torque.

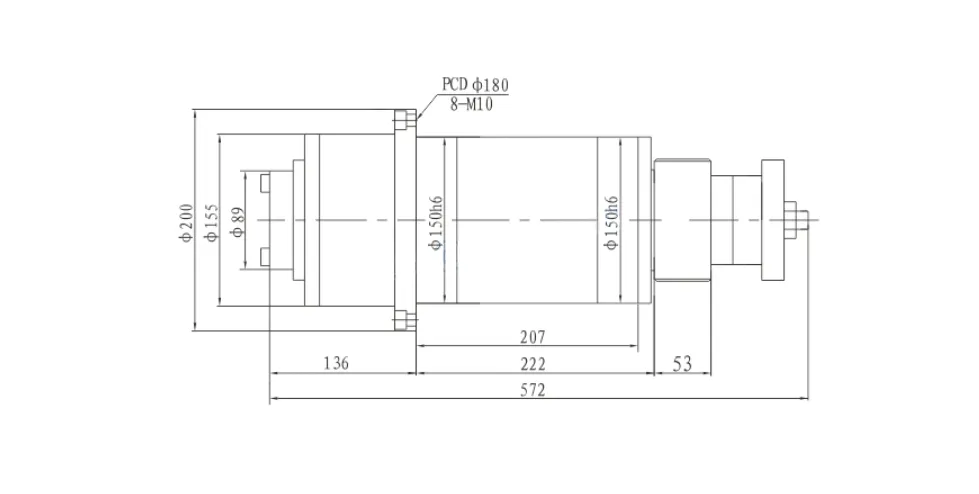

- Spindle Assembly: The spindle assembly consists of the spindle motor, spindle shaft, and bearings. The spindle shaft is the main shaft that connects the motor to the cutting tool or workpiece. Precision bearings are used to support and maintain the spindle’s rotational accuracy and minimize vibration during operation.

- Tool Holding System: The spindle unit incorporates a tool-holding system that securely holds the cutting tools. Common tool-holding systems include collets, tool holders, or automatic tool changers (ATCs). The type of tool-holding system used depends on the specific requirements of the CNC machine center.

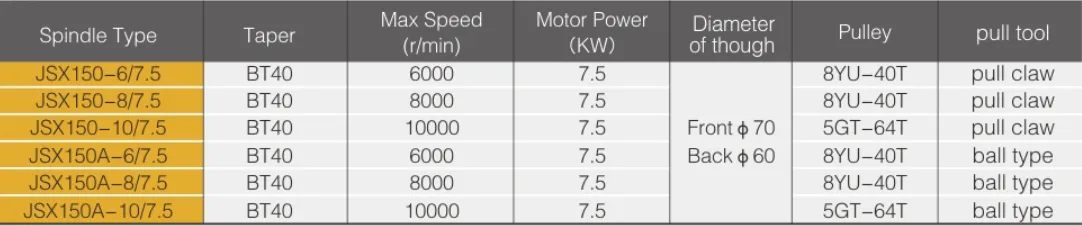

Spindle units in CNC machine centers vary in specifications, such as maximum rotational speed, power output, and tool holding capacity, depending on the specific requirements of the machining center and the intended machining applications. Selecting the appropriate spindle unit is essential for achieving efficient and accurate machining operations.

1. The pull claw can be selected with BT, CAT, or DIN specifications. It has two types of broach mechanisms, one is the steel ball type, and the other is the pull claw type. The steel ball type stroke is 7~9mm, and the pull claw is 5~7mm.

2. The form of the pulley can be specified by the customer.

3. The broaching force is 7500N + 10% and recommended gas-liquid pressurized cylinders should be to 4.5T.

4. Distance 300mm runout: near the end is ≤0.002, and the far end is ≤0.007.

5. Accept the unique specifications of customers.